ZeeSports Knocking Service

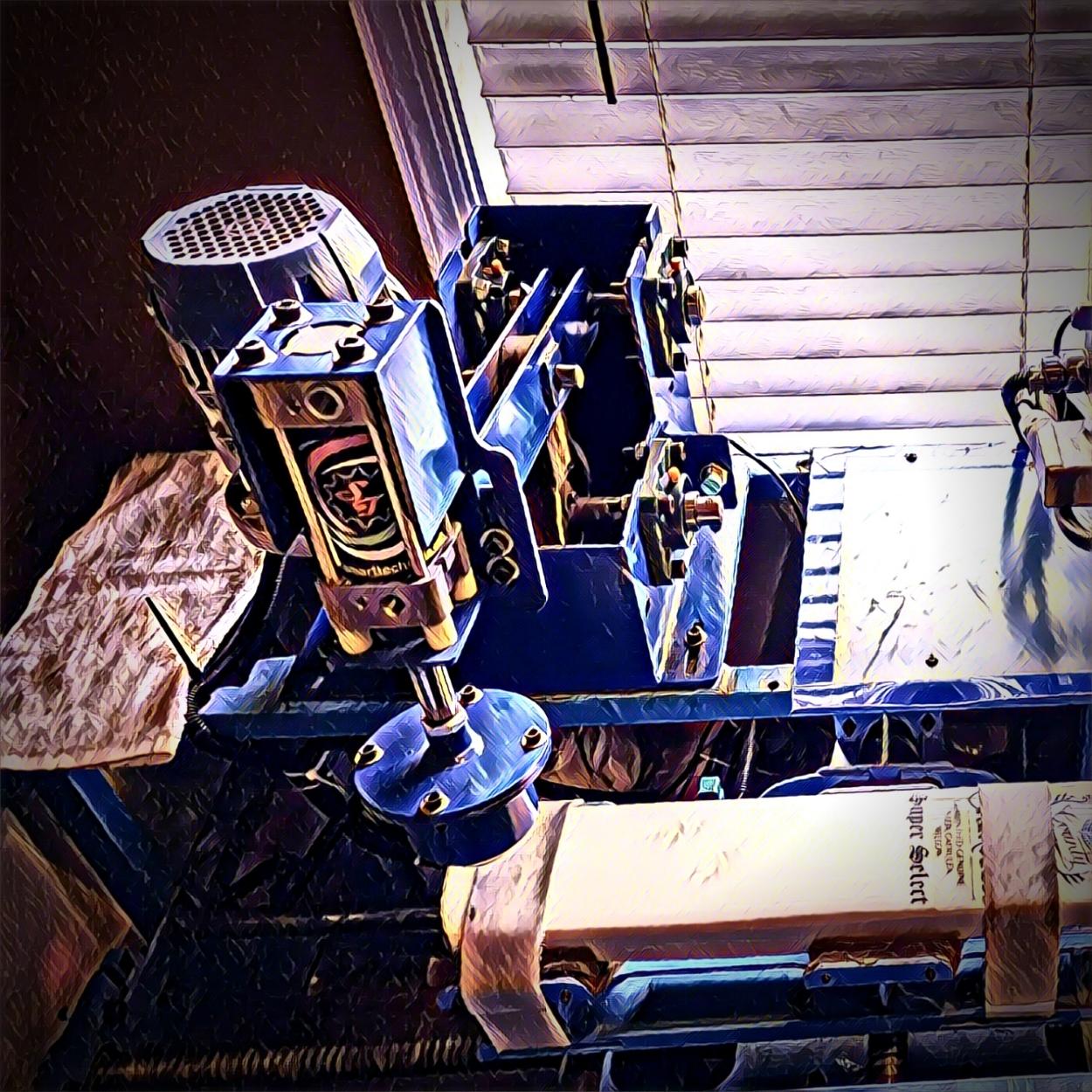

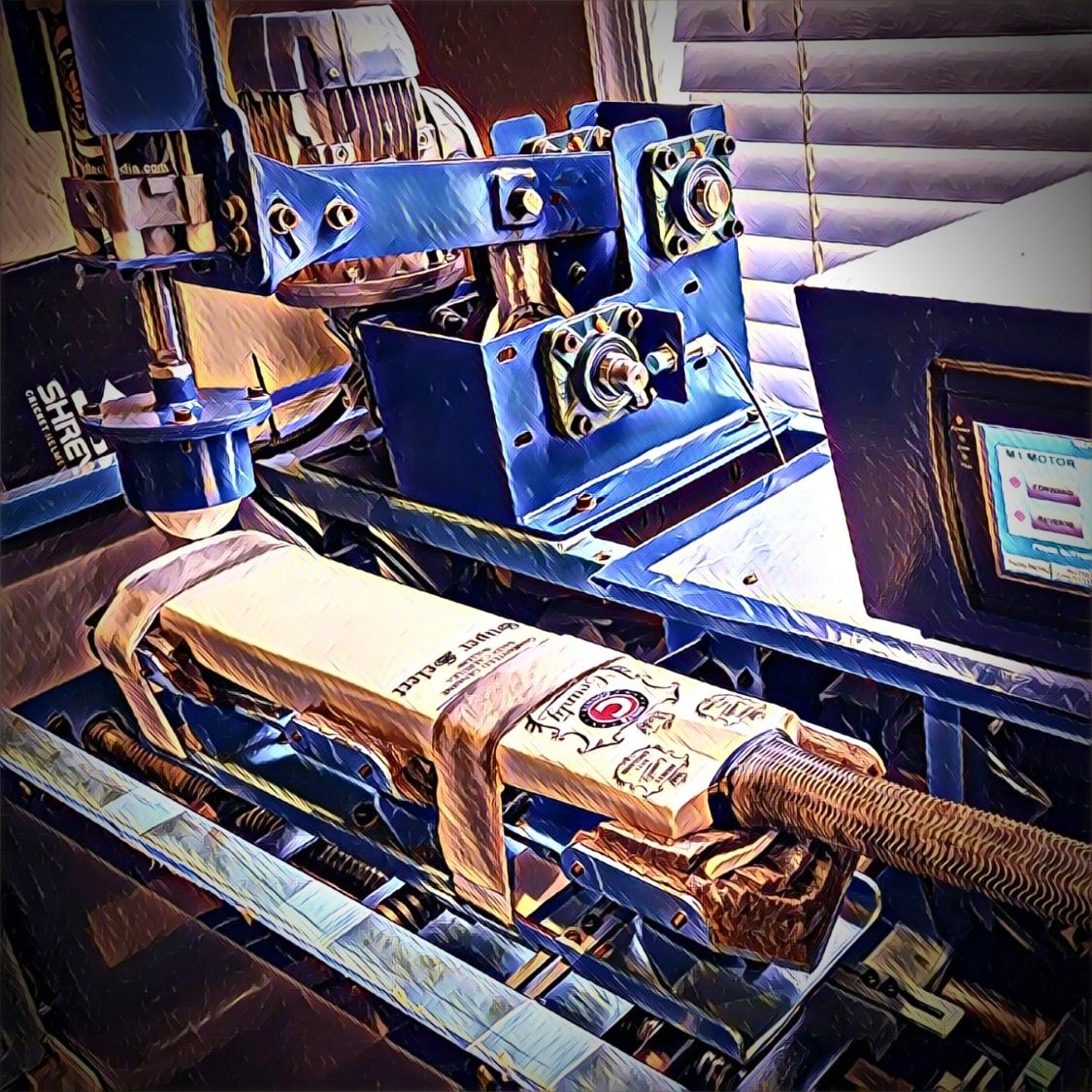

We provide a machine-knocking service per our customer's demand. Also, provide plenty of knocking tools.

The Perfect TOOLS

Discounted Bat Knocking Service With Cricket Bat Purchase, Click Here!

A new cricket bat is an investment:

We providing a professional knocking service for your own bats, We Guaranteeing optimal durability when you step onto the field.

Please note: This exclusive service is provided by ZeeSports specifically for your own cricket bat. Kindly be informed that you are responsible for dropping off your bat at our designated location. You have the flexibility to either send us your bat via courier or visit our physical store personally. Rest Assured, we will handle your bat with the utmost care and expertise to deliver exceptional knocking-in results.

Knocking Your Cricket Bat: A Comprehensive Guide

Knocking your cricket bat is an essential process to ensure its durability, performance, and longevity. Whether you’re a professional cricketer or a casual player, understanding how to properly knock in your bat can make a significant difference in your game. Below, we’ve compiled a detailed FAQ to answer all your questions about knocking, including its benefits, drawbacks, and step-by-step instructions.

Knocking Guide & Details

Knocking is the process of compressing the fibers of a cricket bat’s willow blade to strengthen it and prepare it for use with a leather cricket ball. This is done by repeatedly striking the bat’s surface with a wooden mallet or using a specialized knocking machine. The process helps to harden the bat, reduce the risk of cracking, and improve its overall performance.

Modern cricket bats are made from English Willow or Kashmir Willow, which are naturally soft woods. While this makes the bat lightweight and responsive, it also makes it prone to damage when struck by a hard leather ball. Knocking helps to:

- Compress the fibers of the willow, creating a protective layer.

- Prevent cracking and splitting, especially on the edges and toe.

- Enhance durability and extend the bat’s lifespan.

- Improve performance by creating a larger sweet spot and better rebound.

Without knocking, a new bat is at risk of breaking during its first few uses, especially when facing hard leather balls.

Pros of Knocking

- Increased Durability: Knocking strengthens the bat, making it less likely to crack or break.

- Better Performance: A well-knocked bat has a larger sweet spot and improved rebound.

- Cost-Effective: Properly knocking your bat can save you money by extending its lifespan.

- Customization: Hand knocking allows you to focus on specific areas of the bat that need extra attention.

Cons of Knocking

- Time-Consuming: Knocking can take several hours or even days to complete.

- Physical Effort: Hand knocking requires significant effort and can be tiring.

- Risk of Over-Knocking: Excessive knocking can damage the bat, especially if done incorrectly.

- Machine Limitations: Machine knocking may not cover all areas of the bat, such as the edges and toe.

Steps of Knocking Process

- Why Oil? Oiling moisturizes the willow, preventing it from drying out and cracking.

- How to Oil: Apply 2-3 tablespoons of raw linseed oil evenly to the face, edges, and back of the bat. Avoid oiling the handle, splice, and label.

- Drying Time: Let the bat dry horizontally for 24 hours. Repeat the oiling process 2-3 times if the bat is new or lacks a protective cover.

- Tools Needed: A wooden cricket mallet or hammer mallet.

- Process: Start by gently tapping the edges of the bat at a 45-degree angle. Gradually increase the force as you move to the face and toe.

- Duration: Spend 2-3 hours on this stage, focusing on rounding the edges and compressing the face.

- Re-Oil: After 3-4 hours of knocking, apply a thin layer of oil to keep the bat moisturized.

- Continue Knocking: Use the mallet to knock the bat for another 2-3 hours, focusing on the toe and edges.

- Test the Bat: Bounce a leather ball on the bat’s surface. If no seam marks or dents appear, the bat is ready.

- Optional Protection: Apply fiber tape to the edges and an anti-scuff sheet to the face for added durability.

- Soft Practice: Use an old leather ball to gently play with the bat, gradually increasing the intensity.

- Net Sessions: Test the bat in net sessions before using it in a match.

Machine vs Hand Knocking

- Pros: Faster, more consistent, and requires less physical effort.

- Cons: May miss critical areas like the edges and toe. Requires additional hand knocking for optimal results.

- Pros: Allows for precise control and customization. Ensures all areas of the bat are properly compressed.

- Cons: Time-consuming and physically demanding.

FAQs About Knocking

- Knocking typically takes 6-8 hours, spread over several days. For optimal results, some bats may require up to 20,000 knocks.

- Yes, but machine knocking should be followed by hand knocking to ensure all areas of the bat are properly compressed.

- Yes, even pre-pressed bats require knocking to further compress the fibers and prepare them for match use.

- Without knocking, your bat is at risk of cracking, splitting, or breaking during use, especially when facing hard leather balls.

- While possible, using a ball is less effective than a mallet and may leave seam marks on the bat.

Knocking your cricket bat is a vital step in ensuring its durability and performance. Whether you choose to knock by hand or use a machine, the process requires time, effort, and attention to detail. By following the steps outlined above, you can prepare your bat for the rigors of the game and enjoy optimal performance on the pitch. Remember, a well-knocked bat is not just an investment—it’s your best ally on the field!